Products old

We provide flexibility in pallet size as per customer’s requirement for movement & export of packaged materials such as jumbo bags, drums, carboys, boxes as per requirement. Accordingly, we provide best suitable pallet design to our customers at a very competitive rates.

Some of the running sizes we provide only for export packaging are:

Aimed at effective strength and to ensure load capacity we use sheet metal screws for enhanced fitting of the planks together into one pallet.

We provide 3 tons static load capacity while 1 to 1.5 tons dynamic load capacity. (Depends on the design)

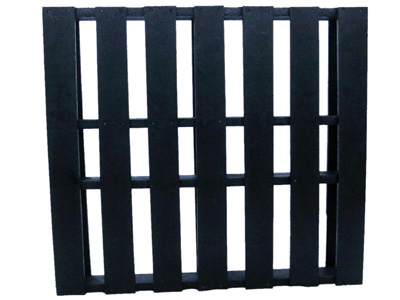

HDPE/PP Pallets

HDPE expands as High-Density Polyethylene and PP as Polypropylene. As the name only clarifies that it is a high-density polymer with high molecular weights. They can withstand higher temperatures as compared to LDPE and other types of polymer. HDPE is known for its large strength to density ratio. The density of high density polyethylene can range from 0.93 to 0.97 g/cm3. HDPE has little branching, giving it stronger intermolecular forces and tensile strength than LDPE. It is also harder and opaquer and can withstand somewhat higher temperatures (120 °C/ 248 °F for short periods, 110 °C /230 °F continuously). High density polyethylene, unlike polypropylene, cannot withstand normally required autoclaving conditions.

Advantages of HDPE plastic pallets over wooden pallets:

| No | Wooden pallets | HDPE Plastic pallets |

|---|---|---|

| 1. | Wooden pallets involve iron nails and sharp edges which results into the damage of jute or plastic bags when placed on it. | Plastic pallets are made with no use of nails. So, there is definitely no chance for the damage of bags and goods on it. |

| 2. | Wooden pallets because of its properties generate bacteria and fungus increasing the vulnerability to diseases, harmful to human health and affecting adversely the strength of pallets. | Plastic pallets are atmosphere resistant and due to properties of plastic, no bacteria or fungus is generated and hence its strength is also enhanced. Thus it is healthy for use and no fumigation or heat treatment is required. |

| 3. | Life span of wooden pallets is as short as around 3 to 4 months or maximum 6 months. If damaged it can be repaired but repairing again and again ultimately creates problems. | Life span of plastic pallets stretches up to as high as 8 to 10 years, if properly operated and handled. Also the strength of these pallets is far better than wooden pallets. |

| 4. | A 10 to 15% wastage of food products has been recorded which adversely affects the economy of the country due to the use of wood for pallets and other articles. The use of wooden pallets forms a major reason for deforestation round the world. | The use of plastic pallets helps to avoid 10 to 15% wastage of food products thereby helping the economy of the country grow. These are made from recyclable plastic material that even helps for pure and healthy environmental sustainability along with the green revolution. |

| 5. | Wooden pallets are not water resistant and therefore they cannot be cleaned properly and also leads to impurity and unhygienic conditions. | Plastic pallets are inert to water which can be considered as a major advantage as they can be cleaned easily and also hygienic. |

| 6. | Due to the use of nails and rust, it increases the risk of employee’s strain and injuries. | Plastic pallets are very easy and harmless in handling and operating due to smooth edges, no use of nails and no possibility of rust. |

| 7. | Wooden pallets are not eco friendly as they are manufactured at the cost of valuable trees in the large number resulting in the depletion of natural resources. | Plastic pallets are manufactured from recyclable plastic material helping in directly saving the trees and thereby retaining the natural resources. |

| 8. | No option of colour or separate identity is possible. | Plastic pallets are available in wide varieties of colour and design. |